1. D236 CRDI Injector Nozzle Part Number Common Writing

D236, L236PBC, 236PBC, 236, L236

2. D236 CRDI Injector Nozzle Quality Control

(1) CRDI Injector Nozzle Testing

All the CRDI injector nozzles are subjected to precision testing, high temperature testing, low temperature testing, withstand pressure testing, leakage testing, durability testing, and various working conditions testing.

(2) CRDI Injector Nozzle Inspection

The factory inspection of the CRDI injector nozzle is undergone full inspection, random inspection, and batch inspection three inspections. Different brands of test benches are used to test the same CRDI injector nozzle for a total of no less than three times for factory inspection, and the fuel injector installation testing environment are progressed in dust-free workshop.

(3) CRDI Injector Nozzle Installation

When matching the CRDI injector nozzle body and nozzle needle, Shumatt strictly complies with the standard of CRDI injector nozzle body and nozzle needle clearance technical indicators to ensure that each CRDI injector nozzle meets the factory standards and use standards.

3. D236 CRDI Injector Nozzle Technical Support

D236 Diesel CRDI Injector Nozzle Installation

The torque lever and tightening moment specified in the injector maintenance manual must be installed when the CRDI injector nozzle is installed. (50Nm)

Pic No.1

The tightening torque of the nozzle cap must be installed in accordance with the tightening torque specified in the injector maintenance manual.

4. D236 CRDI Injector Nozzle Testing After Maintenance

(1) After installation, it needs to be tested on the test bench.

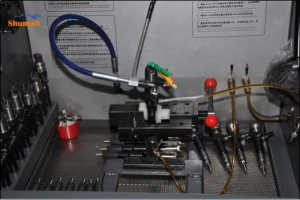

Pic No.2

The correct injector type should be selected for testing

(2) The test results need to be ensured that the following items are within the standard data range of the test stand.

LEAK TEST: Test whether sealing test is up to standard or not

(1) In this step, no injector collector should be installed at the nozzle during the test so as to observe whether the nozzle is dripping oil, meanwhile observe that all joints are no oil leaking.

(2) The static oil return of the test should not exceed 8mm2/H, otherwise, you need to check whether the high-pressure sealing ring, valve assembly, and stroke parameters of the injector are within the standard range.

VL: Test whether full load oil (main injection, high speed) is up to standard or not

(1) This step needs to be combined with vehicle driving conditions, such as power, fuel consumption and smoke as well as the maintenance of the engine, if there is situation of insufficient power, fuel consumption is high, thick black smoke and irregularly maintenance of the engine, the engine needs to be maintained according to the maintenance handbook at very first time.

(2) Each of injector part needs to be adjusted and checked if there is any damage according to above situations to ensure the injector is normal. After make sure the injector works normal, you need to reduce the armature stroke if too much oil injection, and increase the armature stroke if too little oil injection.

(3) The error of each injector should be controlled in 6mm3/HH when adjusting.

TL\EM: Test whether the torque point, emission point, exhaust limit, fuel supply reach standard or not

(1) Through this test, it is detected that when the oil injection is too little, the engine’s acceleration is slow, vice versa, when the oil injection is too much, the engine’s acceleration will produce black smoke and the engine excessive exhaust emissions.

(2) CRDI injector nozzle spring force gasket, armature stroke, lift gasket and solenoid valve spring force gasket determine whether exhaust restriction and injector fuel supply reach standard

LL: Test if the idle fuel supply reaches the standard

(1) This test detects oil injection is too much will cause engine idle smoke, otherwise if the oil injection too little will cause engine idling easy to stall, or difficult to start.

(2) The uneven of oil injection causes the unstable rotation speed of engine , making noise, and increase the engine swing in the acceleration process.

(3) Each injector error should be controlled within 2mm3/HH when adjusting.

(4) Idle speed fuel supply quantity mainly by adjusting the nozzle spring force gasket.

VE: Test whether the pre-injection meets the standard

(1) This test detects when oil injection is too much will cause cylinder knocking while the engine is working and the exhaust emissions is not up to standard (smoke).

(2) When the amount of fuel injection is too small, the engine will make loud noises during operation, it will be difficult to start the engine, the engine will be weak in acceleration, and the injector will respond slowly.

(3) Each injector error should be controlled within 0.5mm3/HH when adjusting.

5. Copyright Statement

All materials posted on this passage, such as text, charts, logos, images and web page layout design,etc. are subject to copyrights owned by www.crdiinjectornozzle.com and related copyright owners and protected by international copyright laws. Unauthorized use of any materials on this website may violate copyright laws, trademark laws, the laws of privacy and publicity, and communications regulations and statutes.

Any visitors to this website are permitted to use the content for personal, non-commercial purposes only. Any use of the content for commercial purposes, including but not limited to reproduction, modification, distribution, transmission, republication of all or part of any content found on this site is strictly prohibited, unless www.crdiinjectornozzle.com or the copyright owner of the material has expressly granted its prior written permission to reproduce, retransmit, or republish the material.

If there is any question, please contact us via hison@shumatt.com.